Our Wire EDM Services

Delve into our Wire EDM services that offer unparalleled accuracy and intricate detailing.

What is wire edm?

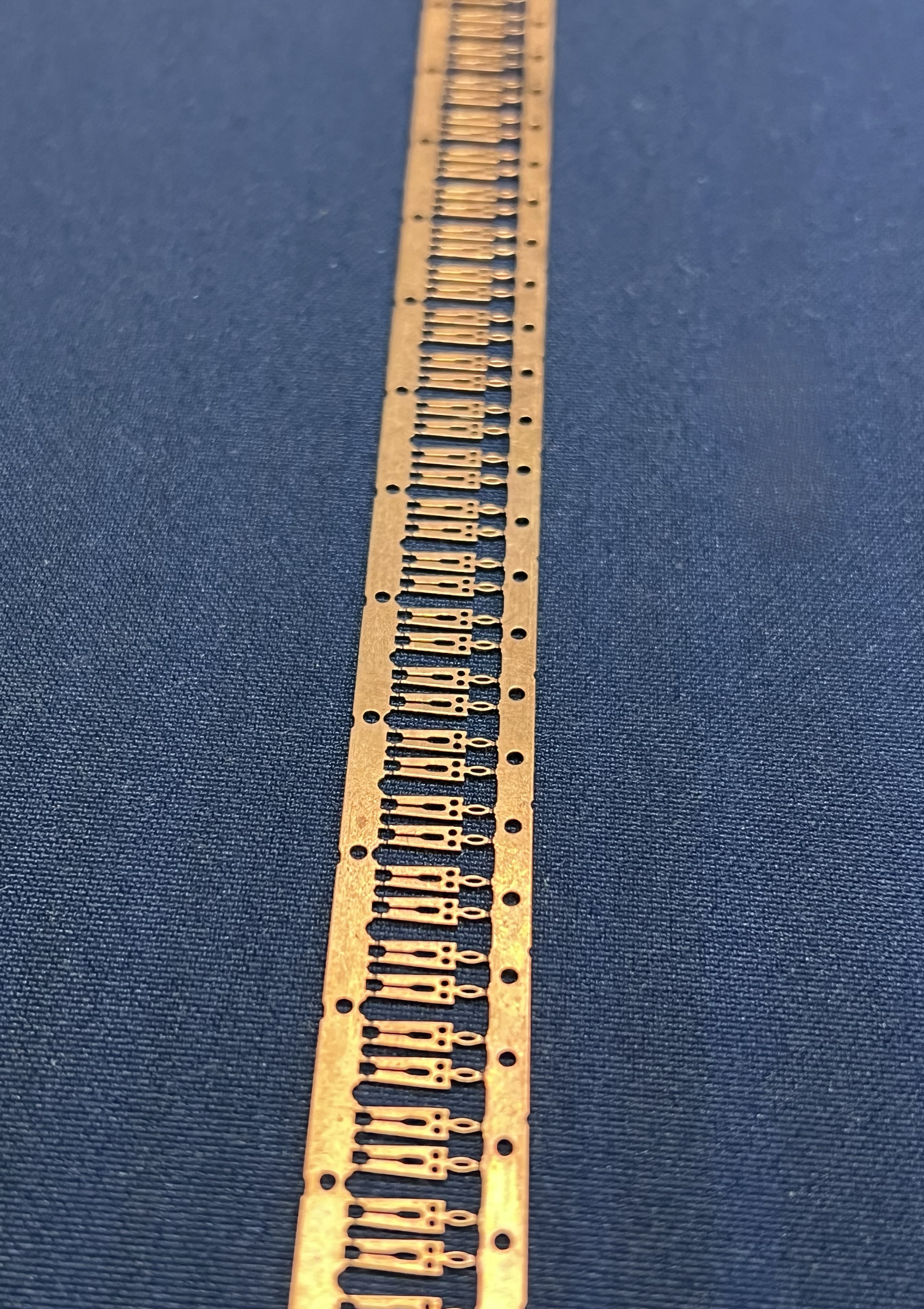

Wire EDM is a precision machining process that uses a thin, electrically charged wire to cut and shape materials. It operates through electrical discharge (sparks) between the wire and the workpiece, removing material with incredible accuracy without direct contact.

how wire EDM Works

Discover the precision and efficiency of Marion Manufacturing’s Wire EDM process, where advanced technology and expert craftsmanship deliver high-quality, intricate components with exceptional accuracy.

Setup

A thin wire, usually brass or copper, is strung between two guides and kept under tension.

Electric Discharge

The wire is energized, creating electrical sparks between the wire and the workpiece submerged in a dielectric fluid (usually deionized water).

Material Removal

The sparks erode material from the workpiece, forming intricate shapes, fine details, or narrow cuts.

Precision Motion

CNC controls guide the wire for intricate designs and complex geometries.

The Benefits of wire EDM

Below are few key factors of why you should consider Wire EDM services.

Precision Finishes

Achieve superior accuracy with tight tolerances and smooth surface finishes, perfect for precision-critical applications.

Non-Contact Process

With no physical contact between the cutting tool and workpiece, Wire EDM ensures minimal distortion, even for delicate or fragile materials.

Extensive Wire EDM Materials We Service

Marion Manufacturing offers wire EDM services for a wide variety of materials, catering to diverse industry needs with precision and efficiency.

Our Top Markets for On-Demand Manufacturing

We excel in delivering high-quality, American-made products tailored to meet the demands of diverse markets. View our full range of industries we serve below.

Our Wire EDM Standards

At Marion Manufacturing, we leverage extensive expertise and advanced technology to offer full-service wire EDM solutions. From concept to completion, our capabilities are designed to meet diverse industry needs with precision and efficiency.

Various Specs & Tight Tolerances

Marion Manufacturing excels in Wire EDM (Electrical Discharge Machining), utilizing a precision single-strand wire and deionized water to cut conductive materials with exceptional accuracy. Our capabilities allow for the creation of complex parts that meet stringent surface smoothness standards without the need for post-processing.

Engineering Support and Production Efficiency

Our team provides comprehensive support, including engineering assistance, project management, and program design. Equipped with a variety of advanced machines, we achieve high production efficiency, managing prototypes to full production quantities without compromising quality.

Reliable and Prompt Delivery

Commitment to timely delivery is at the heart of our operations. We optimize our workflows to ensure that we meet even the most demanding schedules, providing reliable service that you can count on.

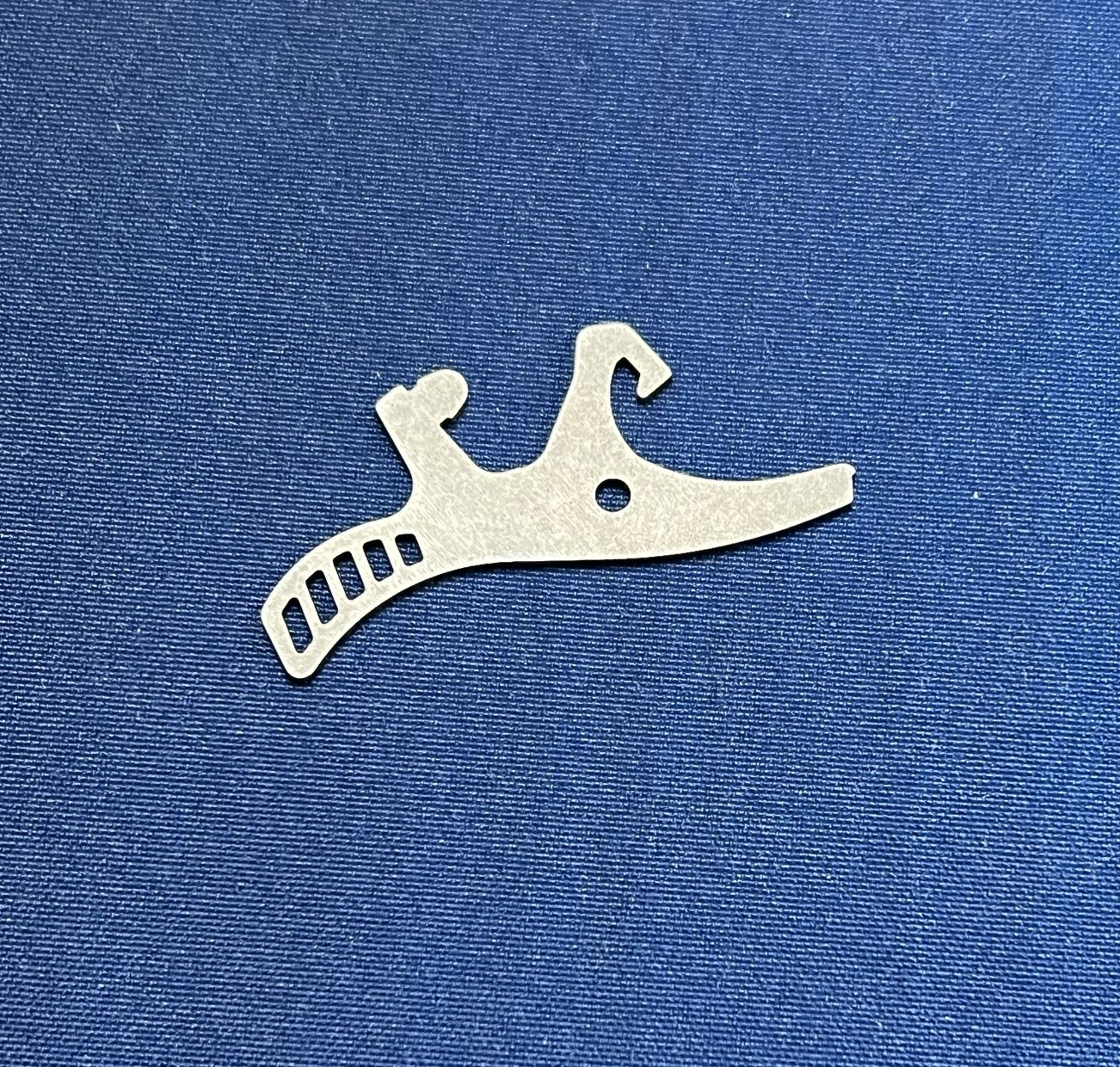

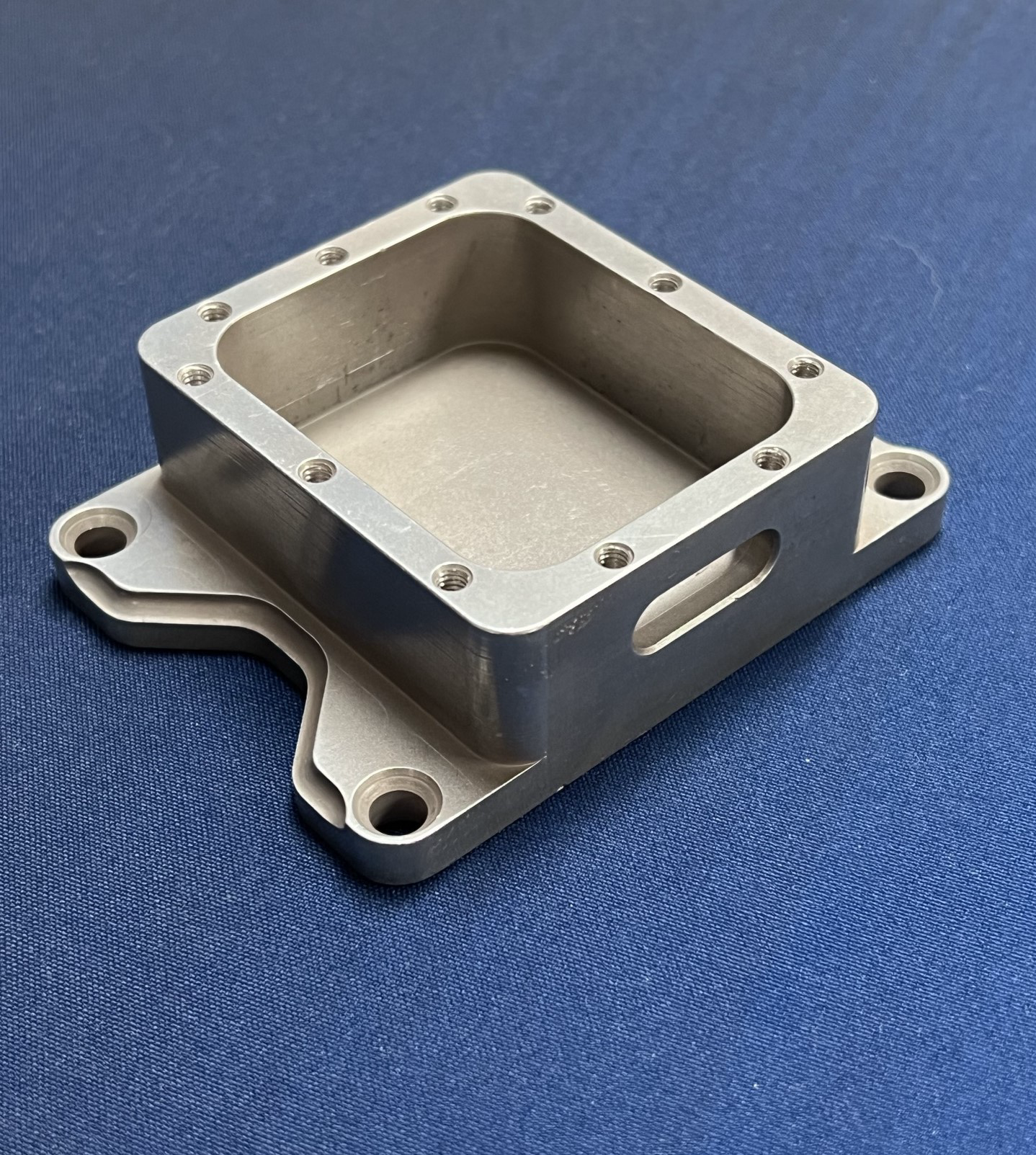

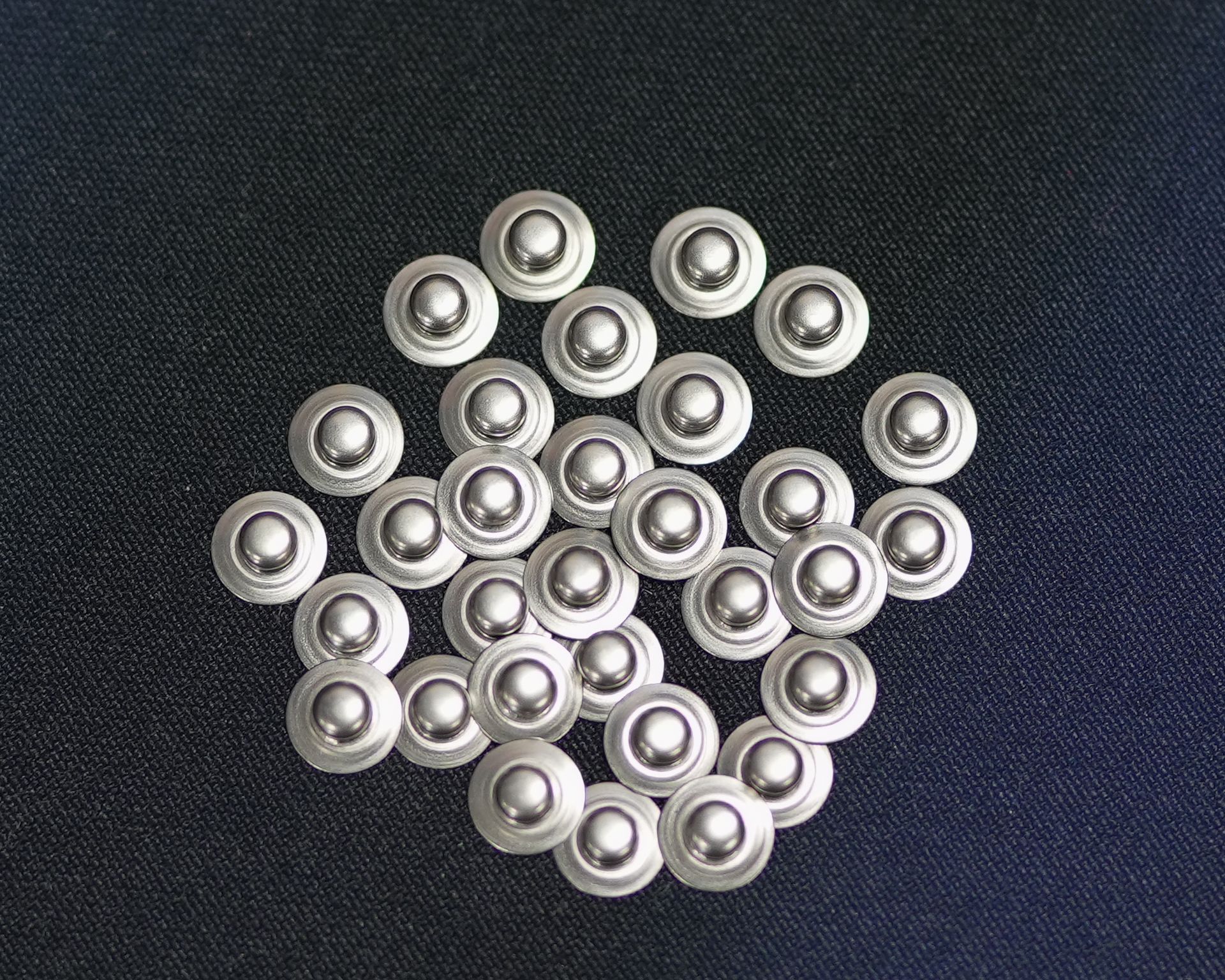

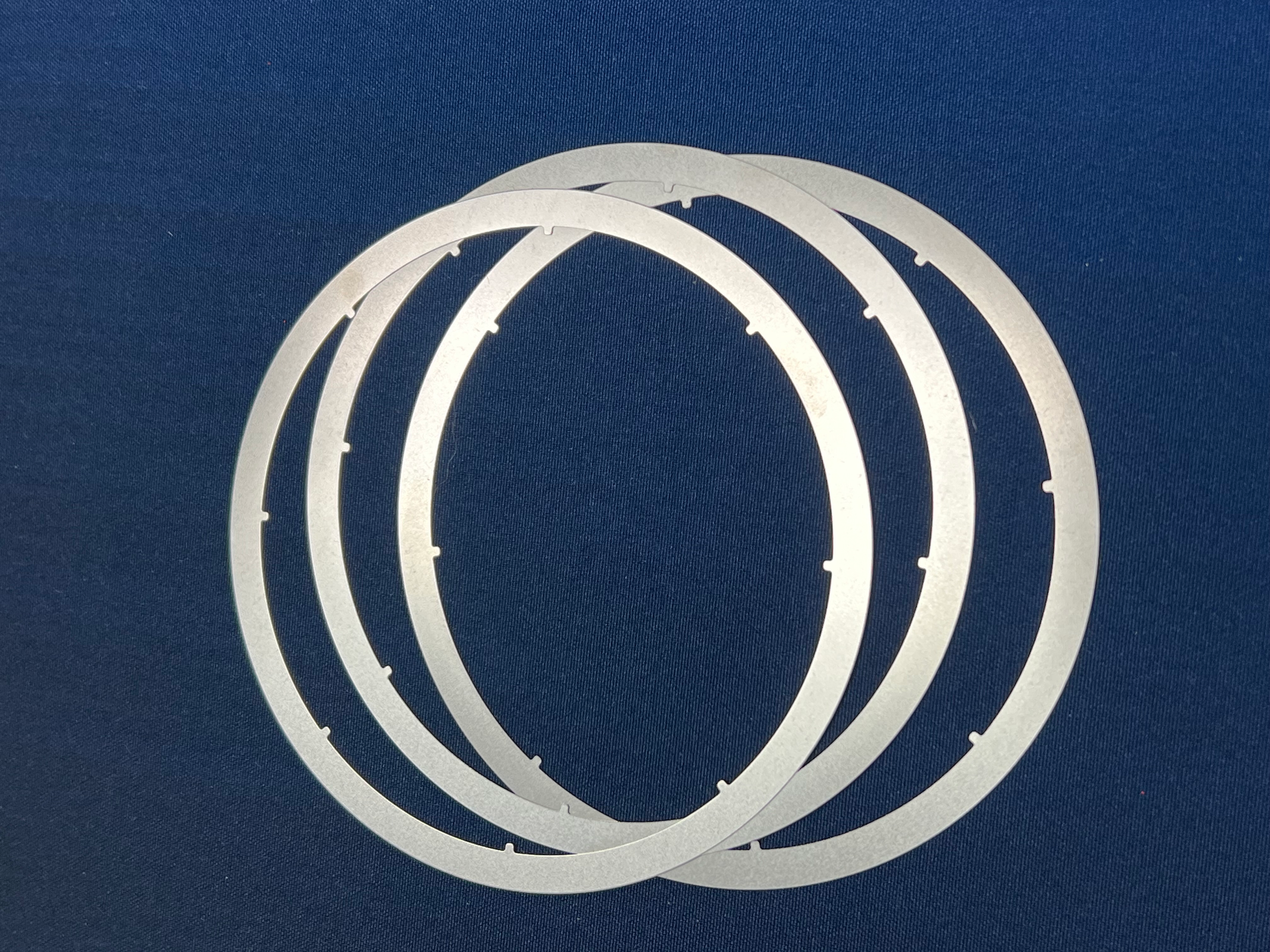

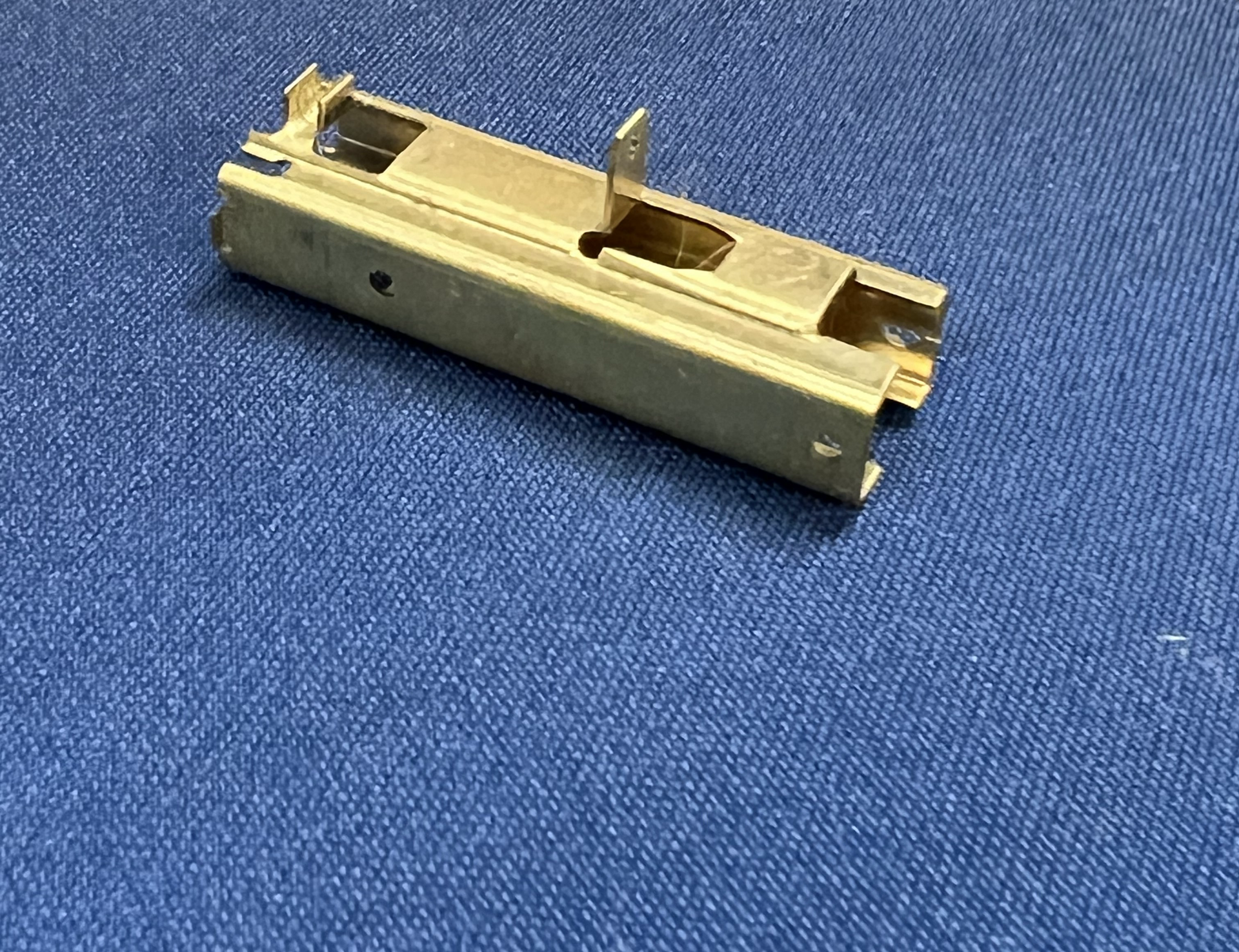

Showcase of Our Manufactured Parts

We manufacture low-high volume production orders for customers in multiple industries: aerospace, automotive, defense, electronics, hardware, startups, industrial automation, machinery, manufacturing, medical devices, oil & gas and robotics.

MARION MANUFACTURING'S FACTORY TOUR

Step Inside and Tour Our Factory

Marion Manufacturing takes pride in operating one of the most advanced factories in the metal stamping and precision components industry. We invite you to watch our factory tour video to glimpse into our advanced capabilities and processes, reflecting our 75-year commitment to excellence in American manufacturing.