Our Plastic Laser Cutting Services

Dive into our plastic laser cutting services, utilizing state-of-the-art technology to achieve intricate cuts and clean finishes on various plastic materials.

Certifications

ISO 9001 | IATF 16949 | ITAR Registered

Our Metal Stamping Capabilities Customized Plastic Laser Cutting

We excel in delivering high-quality, American-made products tailored to meet the demands of diverse markets. View our full range of industries we serve below.

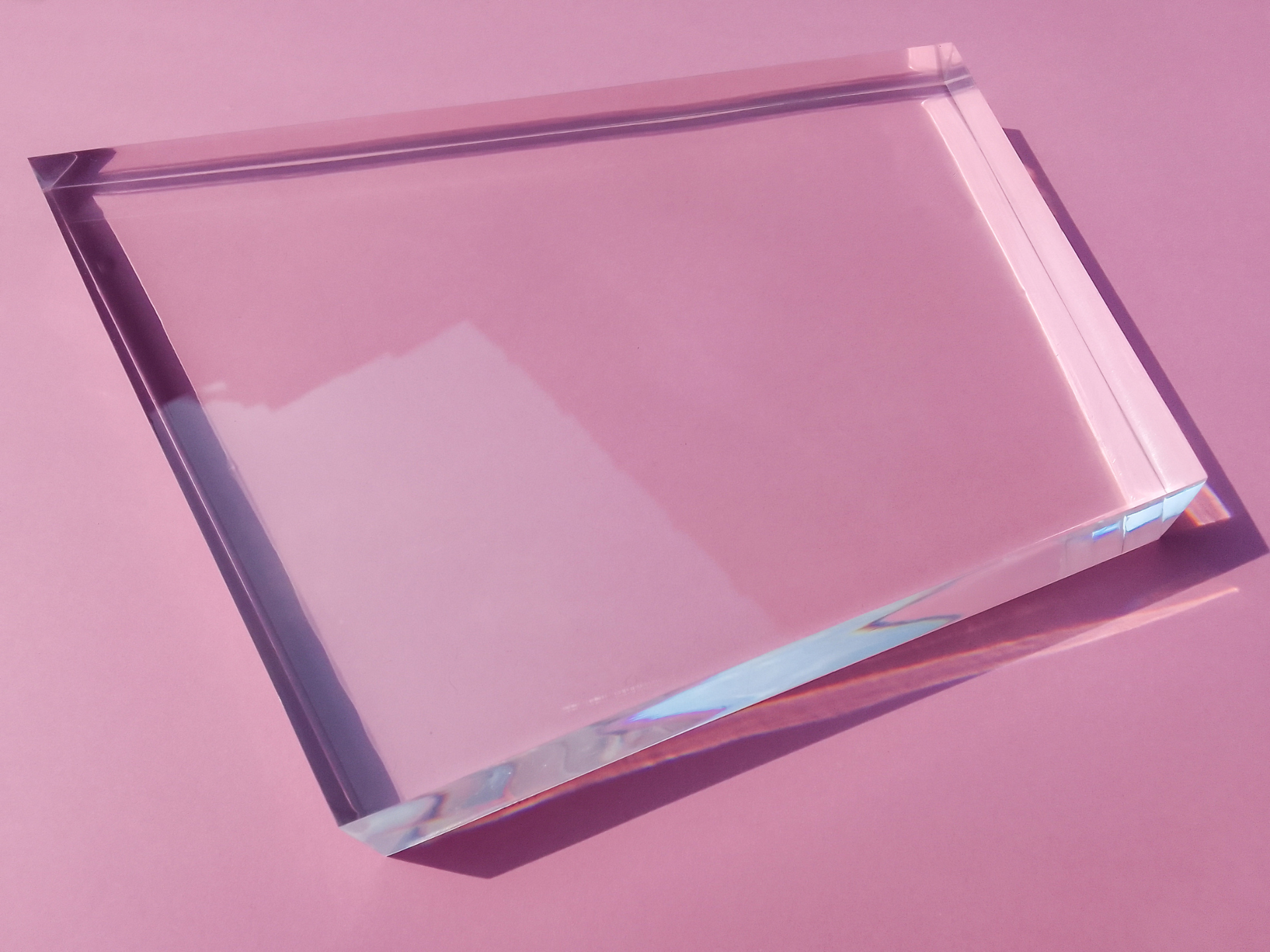

Extensive Plastic Laser Cutting Plastic Materials We Service

Marion Manufacturing offers plastic laser cutting services for a wide variety of materials, catering to diverse industry needs with precision and efficiency.

Our Plastic Laser Cutting Standards

At Marion Manufacturing, we leverage extensive expertise and advanced technology to offer full-service metal stamping solutions. From concept to completion, our capabilities are designed to meet diverse industry needs with precision and efficiency.

Various Specs & Tight Tolerances

Marion Manufacturing's plastic laser cutting technology delivers exceptional precision with kerf thicknesses typically less than 0.010". This precise cutting minimizes the heat effects and warping in plastics, maintaining superior dimensional stability and accuracy in the finished parts.

Engineering Support and Production Efficiency

At Marion Manufacturing, we offer comprehensive support across plastic and metal laser cutting projects. Our team provides engineering expertise, project management, and advanced tool design. With cutting-edge technology, we ensure efficient production from prototype to full-scale output, maintaining high quality across all materials.

Reliable and Prompt Delivery

Commitment to timely delivery is at the heart of our operations. We optimize our workflows to ensure that we meet even the most demanding schedules, providing reliable service that you can count on.

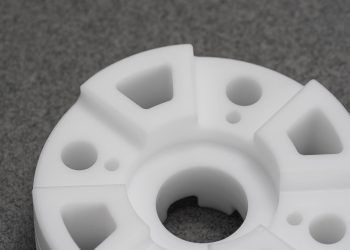

Showcase of Our Manufactured Parts

We manufacture rapid prototypes and low-volume production orders for customers in multiple industries: aerospace, automotive, defense, electronics, hardware startups, industrial automation, machinery, manufacturing, medical devices, oil & gas and robotics.

MARION MANUFACTURING'S FACTORY TOUR

Step Inside and Tour Our Factory

Marion Manufacturing takes pride in operating one of the most advanced factories in the metal stamping and precision components industry. We invite you to watch our factory tour video to glimpse into our advanced capabilities and processes, reflecting our 75-year commitment to excellence in American manufacturing.