On-Demand Telecommunications Manufacturing

Leverage Marion Manufacturing's expertise in on-demand telecommunications manufacturing, where rapid innovation meets industry-leading quality for essential communication components.

Precision Manufacturing for the Telecommunications Industry

At Marion Manufacturing, we serve a diverse range of customers within the telecommunications and new technology sectors, including high-tech communications and energy technology companies. We deliver solutions and quick lead times for projects involving quality

metal stamping,

CNC machining, and

laser cutting

services. Our extensive expertise allows us to support rapid prototyping, large-scale production, and complex project management, all while maintaining stringent quality standards. With a strong commitment to reducing production costs and enhancing manufacturability, our engineering team provides one-on-one communication that helps streamline your production run from concept to completion.

The Marion Manufacturing Standard

At Marion Manufacturing, we leverage extensive expertise and advanced technology to offer full-service manufacturing solutions. From concept to completion, our capabilities are designed to meet diverse industry needs with precision and efficiency.

Quality Assurance

We ensure each product surpasses industry standards, embodying our commitment to reliability and quality excellence.

Production Efficiency

Our team upholds high production efficiency and precision, significantly cutting lead times while enhancing product quality.

Prompt Delivery

We prioritize ensuring on-time delivery, optimizing our workflows to reliably meet even the most stringent timelines.

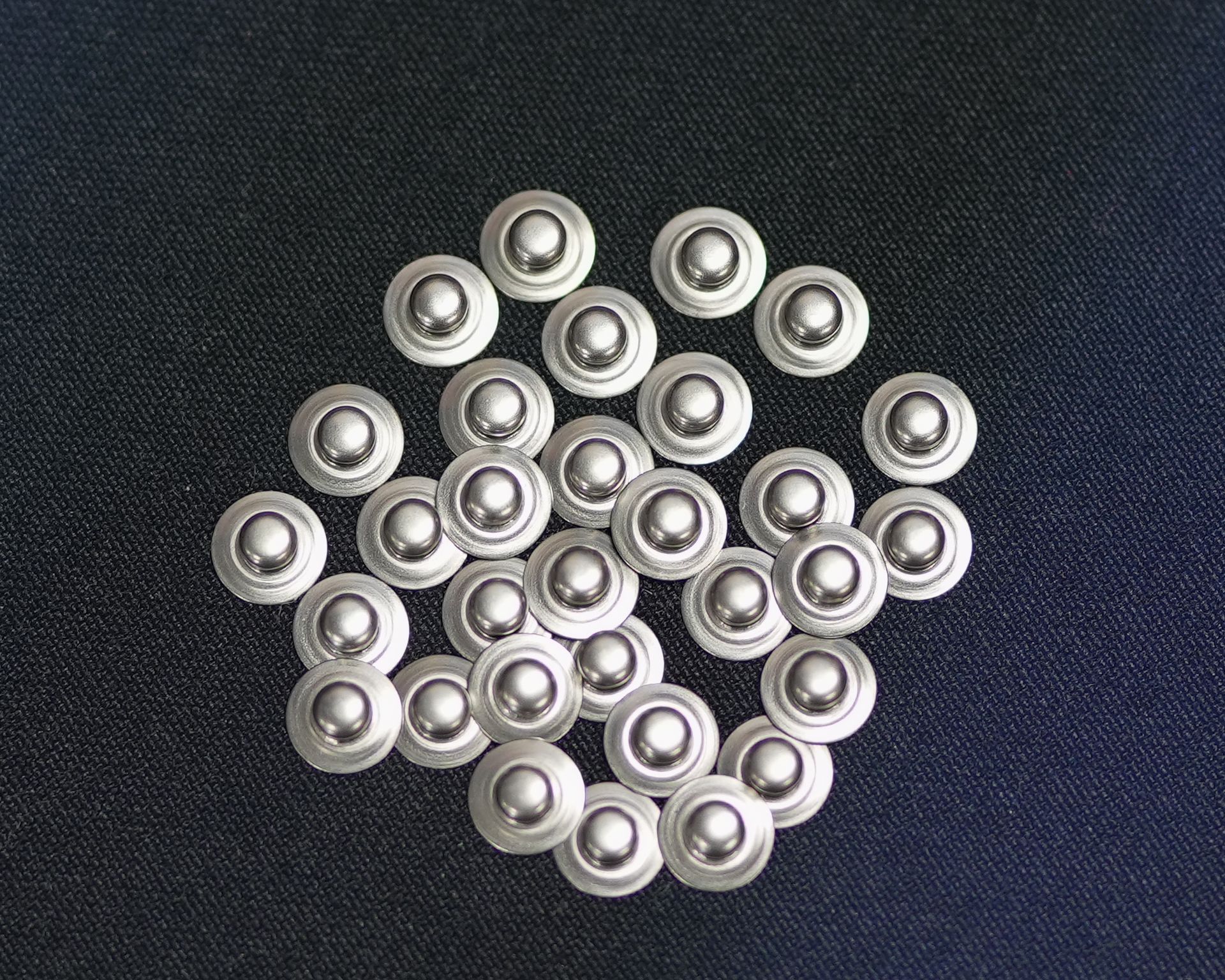

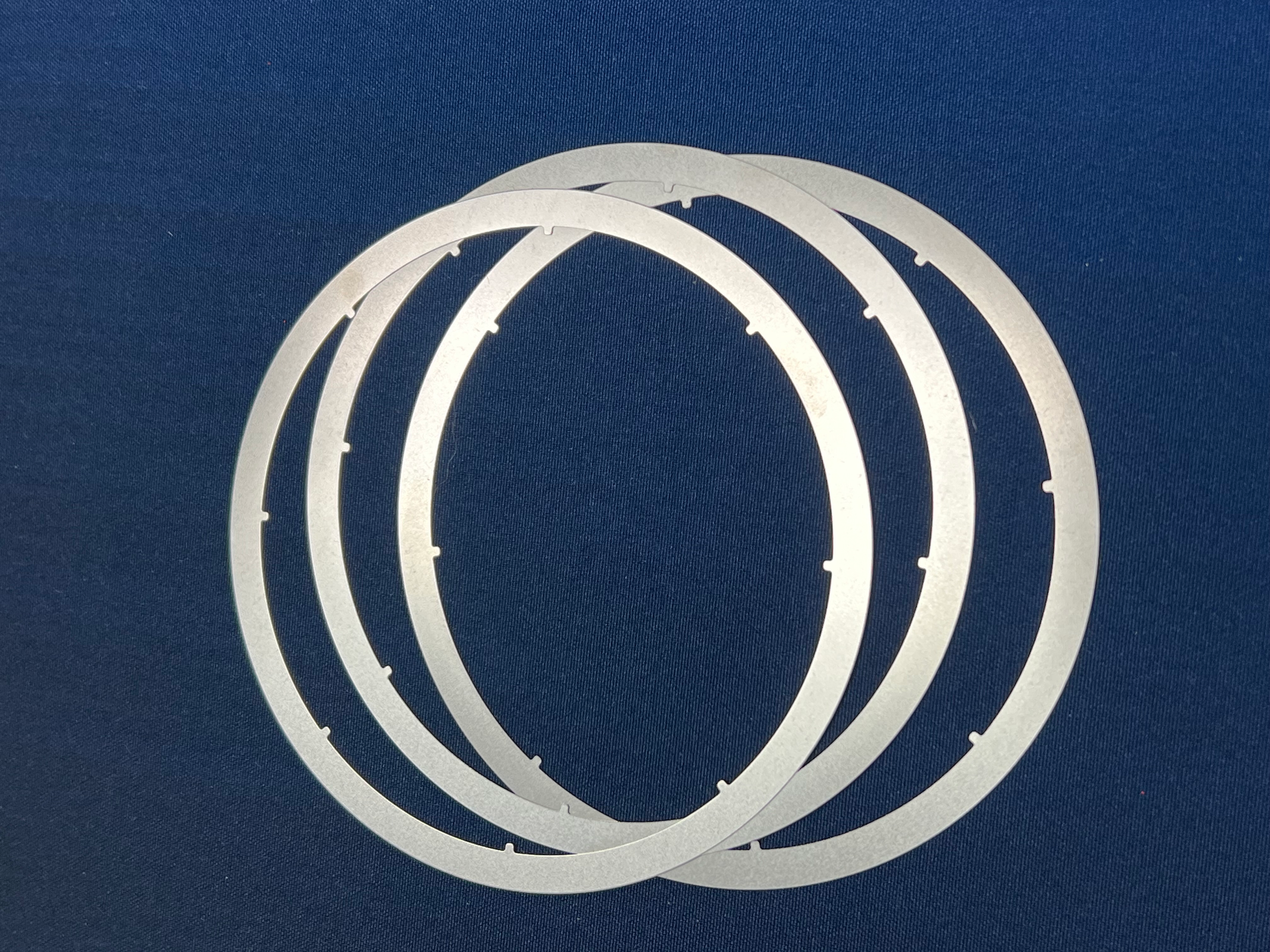

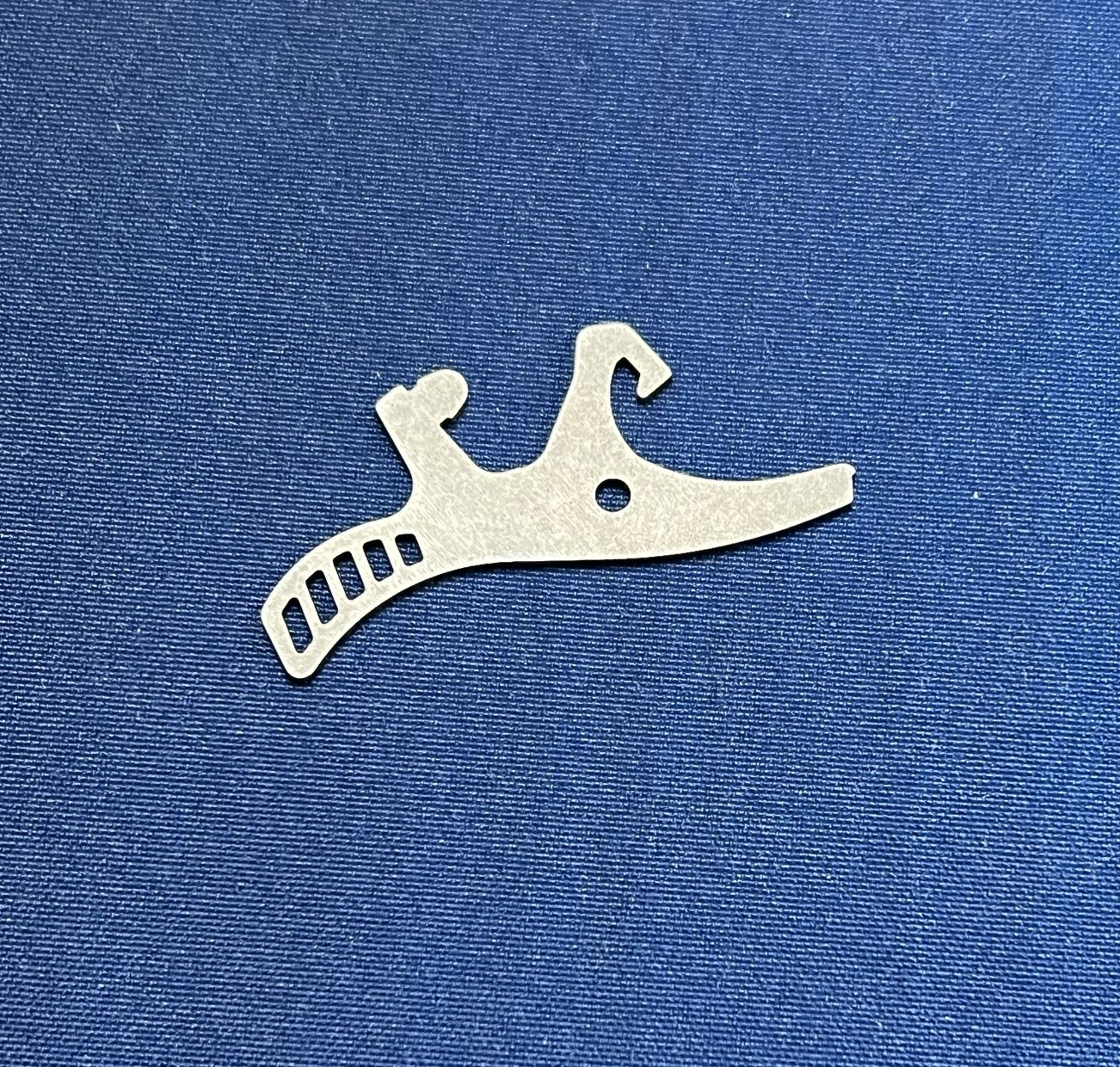

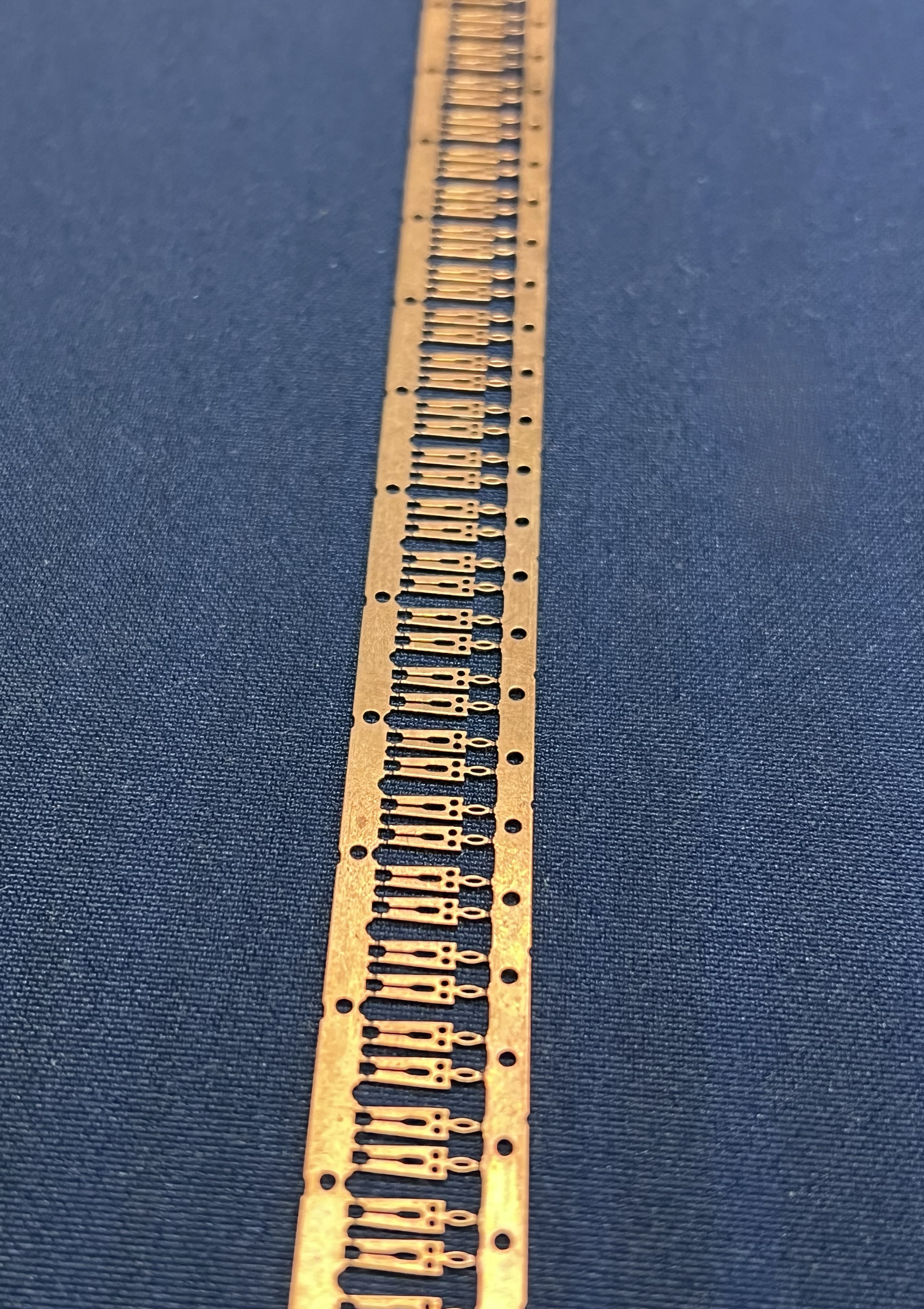

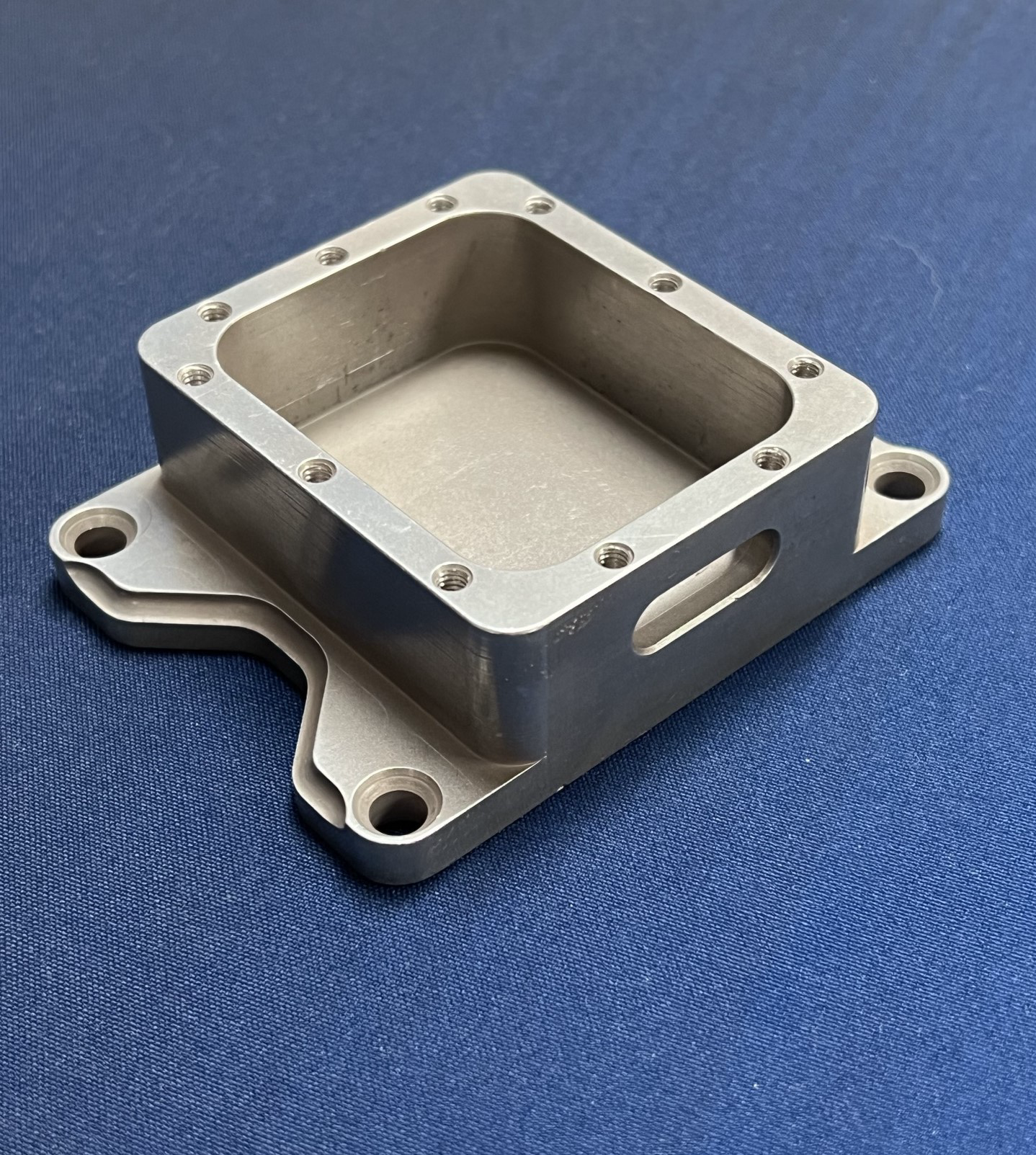

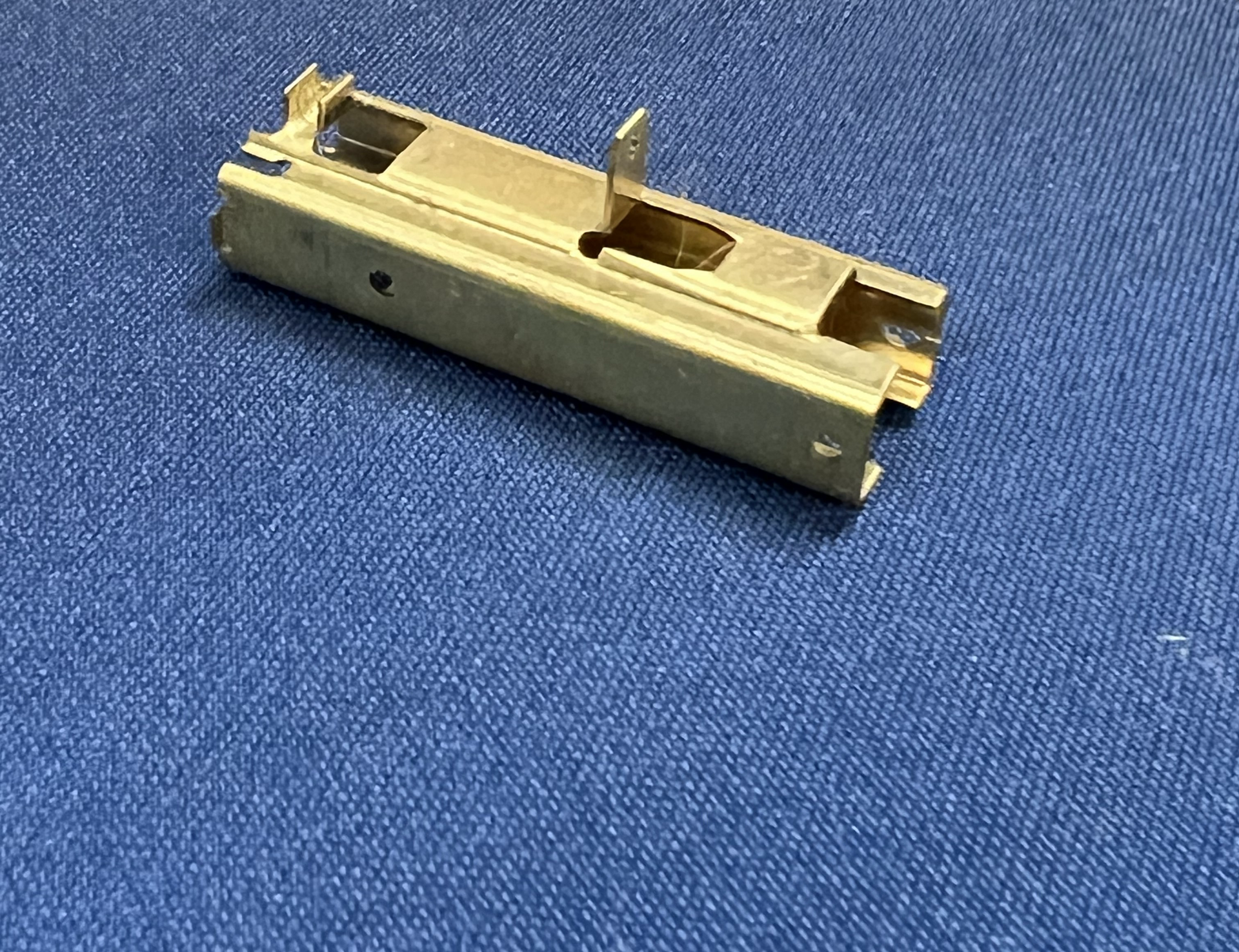

Showcase of Our Manufactured Parts

We manufacture low-high volume production orders for customers in multiple industries: aerospace, automotive, defense, electronics, hardware, startups, industrial automation, machinery, manufacturing, medical devices, oil & gas and robotics.

MARION MANUFACTURING'S FACTORY TOUR

TAKE A TOUR AROUND OUR FACTORY

Marion Manufacturing takes pride in operating one of the most advanced factories in the metal stamping and precision components industry. We invite you to watch our factory tour video to glimpse into our advanced capabilities and processes, reflecting our 75-year commitment to excellence in American manufacturing.