Our Metal Stamping Services

Discover Marion Manufacturing's comprehensive metal stamping services, engineered to deliver precision components quickly and efficiently.

What is Progressive metal stamping

Progressive metal stamping is a manufacturing process that produces parts from coiled strip metal through a series of continuous, automated operations performed by a single machine. This process is commonly used for high volume due to its efficiency, precision, and ability to produce high-quality components repeatedly.

how metal stamping Works

Experience the precision and efficiency of Marion Manufacturing’s Progressive Metal Stamping, delivering high-quality, complex components with unmatched accuracy and speed.

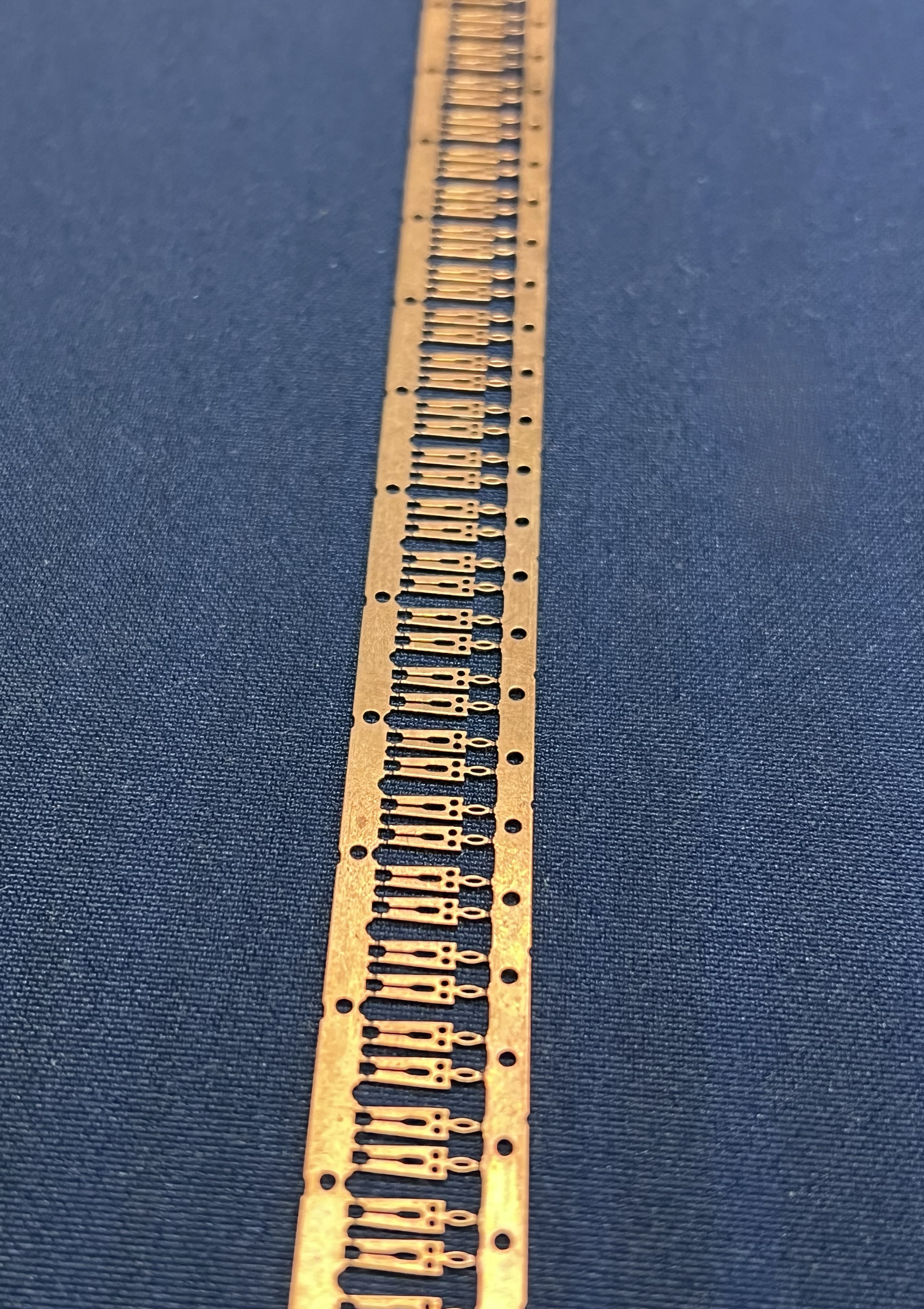

Strip of Metal

A coiled strip of raw metal is fed into the progressive stamping press, serving as the foundation for precision manufacturing.

Progressive Die

The progressive die, a custom-designed tool with multiple stations, performs operations like cutting, punching, bending, and drawing.

Order of Operations

As the metal advances through each station, features are sequentially formed, ensuring precision and consistency with every step.

Finished Part

The completed part is separated from the strip, showcasing precision craftsmanship and ready for its intended application.

The Benefits of metal stamping Services

Below are a few key factors of why you should consider Progressive Metal Stamping services.

Efficiency in Production

Metal stamping delivers high-volume parts quickly and cost-effectively, ensuring consistent results across every production run.

Unmatched Precision

Achieve uniformity and tight tolerances with progressive metal stamping, ideal for applications demanding high accuracy.

Versatile Capabilities

From intricate designs to complex shapes, progressive metal stamping offers unmatched flexibility for diverse manufacturing needs.

Optimized Material Use

Maximize raw material efficiency with minimal waste, making progressive metal stamping an environmentally friendly and cost-saving solution.

Our Metal Stamping Services Customized For You

At Marion Manufacturing, our agility is a distinct advantage in our services, appreciated for the short lead times and high efficiency we offer. We create tailored solutions that effectively tackle significant challenges, consistently exceeding customer expectations.

HIGH SPEED PROGRESSIVE METAL STAMPING

Stamping, forming, assembly

At Marion Manufacturing, we specialize in high-speed progressive metal stamping, utilizing advanced techniques for precision laser cutting, bending, and post-processing. Our team leverages state-of-the-art technology to produce complex components with high efficiency and accuracy, ensuring top-quality results for every project. Trust us to deliver excellence in every stamp.

Extensive Metal Stamping Materials We Service

Marion Manufacturing offers high-speed progressive metal stamping for a wide variety of materials, catering to diverse industry needs with precision and efficiency.

Our Top Markets for On-Demand Manufacturing

We excel in delivering high-quality, American-made products tailored to meet the demands of diverse markets. View our full range of industries we serve below.

Our Metal Stamping Standards

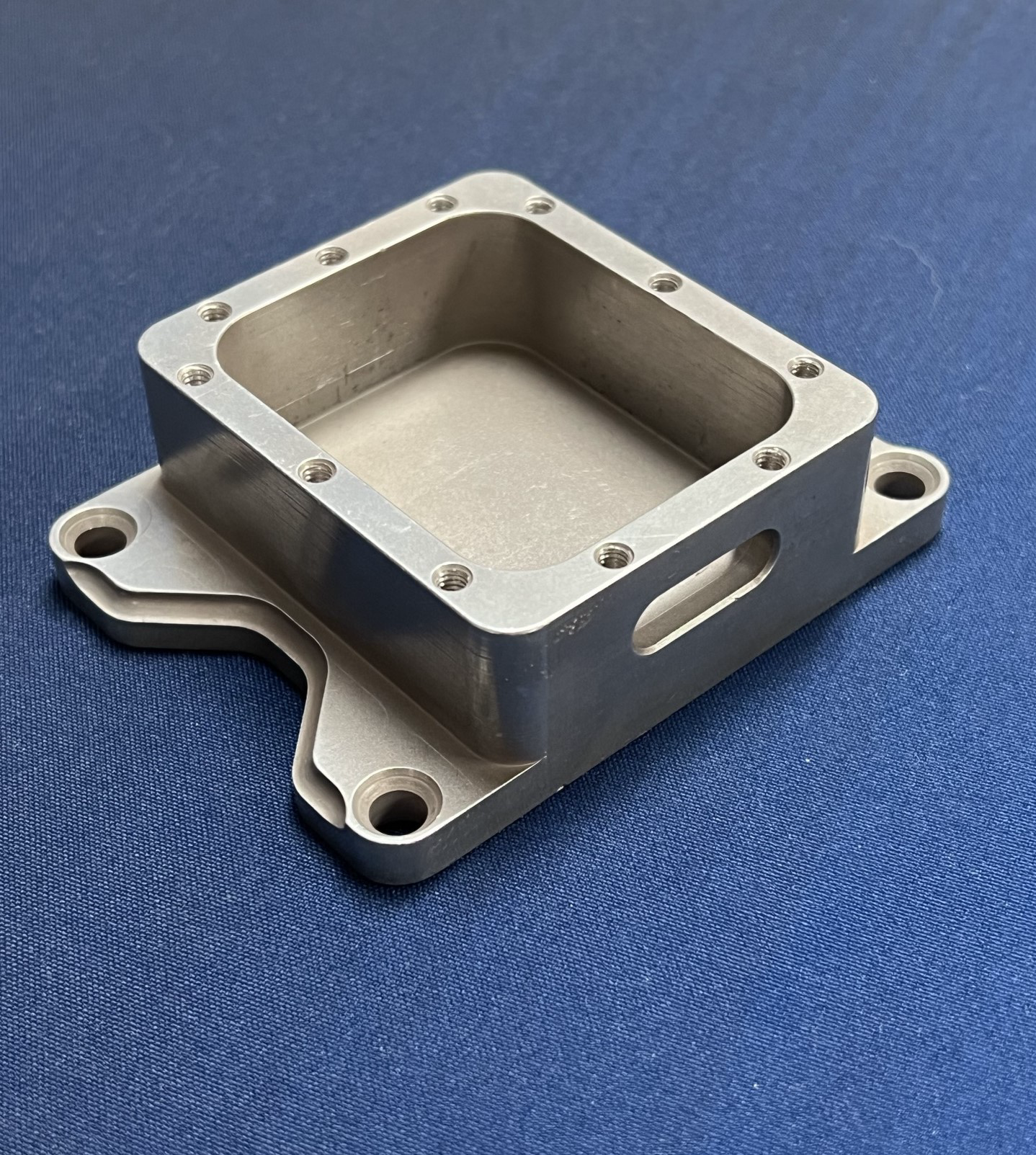

At Marion Manufacturing, we leverage extensive expertise and advanced technology to offer full-service metal stamping solutions. From concept to completion, our capabilities are designed to meet diverse industry needs with precision and efficiency.

Various Specs & Tight Tolerances

Marion Manufacturing processes both ferrous and non-ferrous metals, ranging from .010" to .250" in thickness. We handle specialized projects that require precision tolerances as tight as +/- .0005" on certain dimensions, ensuring each product not only meets but exceeds industry standards.

Engineering Support and Production Efficiency

Our team provides comprehensive support, including engineering assistance, project management, and tool design. Equipped with a variety of advanced stamping presses, we achieve high production efficiency, managing prototypes to full production quantities without compromising quality.

Reliable and Prompt Delivery

Commitment to timely delivery is at the heart of our operations. We optimize our workflows to ensure that we meet even the most demanding schedules, providing reliable service that you can count on.

Marion Manufacturing's Wide-Range of Equipment

At Marion Manufacturing, we are equipped with a diverse array of state-of-the-art metal stamping machinery designed to meet a wide range of manufacturing demands. From intricate small parts to robust large-scale components, our fleet includes:

- Precision Stamping Presses:

- (1) 30-Ton Minster Kiori

- (2) 30-Ton Minster

- (3) 30-Ton Bruderer

- (5) 60-Ton Minster

- (2) 100-Ton Minster

- Advanced CNC Machines:

- (1) CNC HAAS VF2 SS

- (1) Haas Mini Mill

- (1) Haas CNC Lathe ST-10

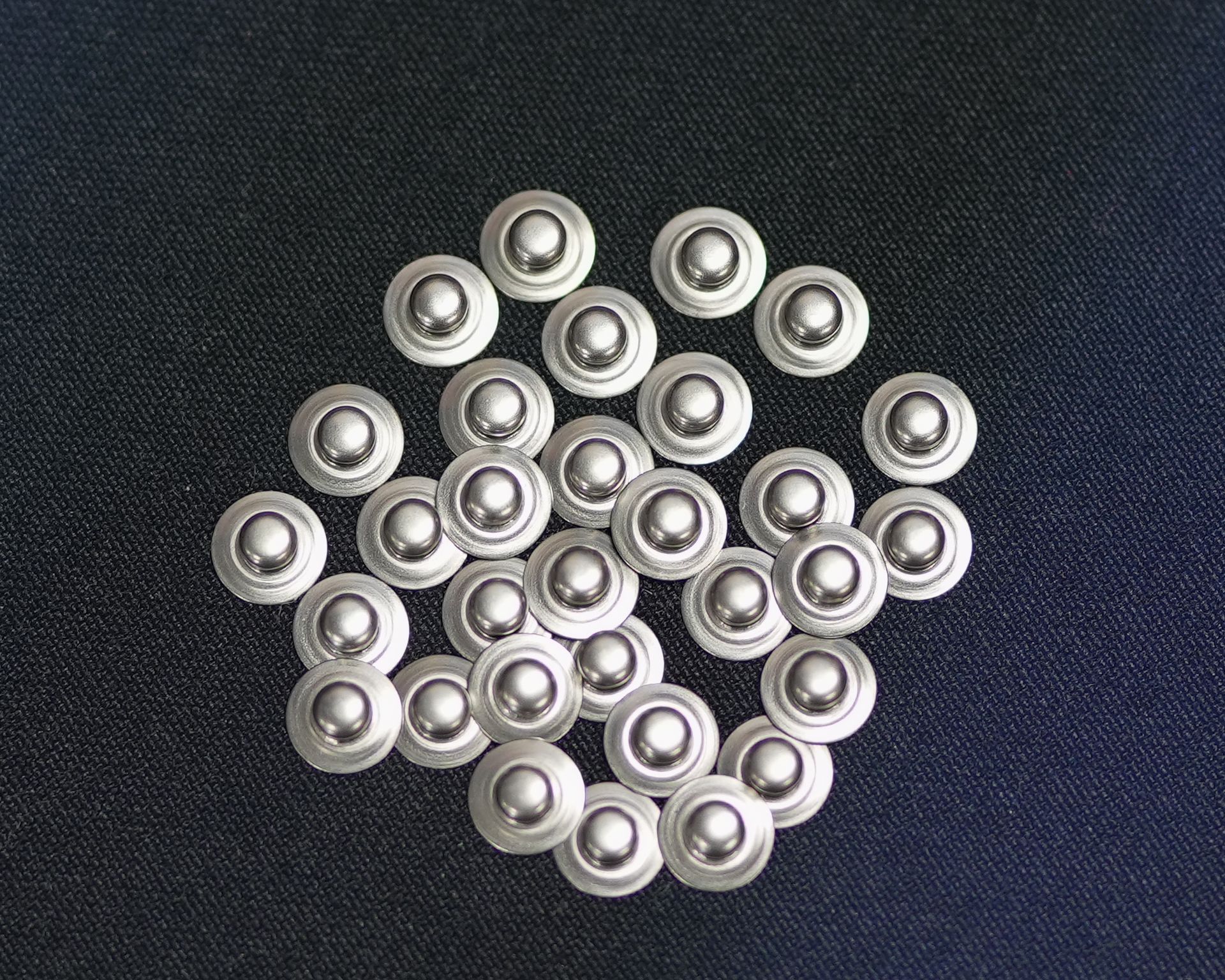

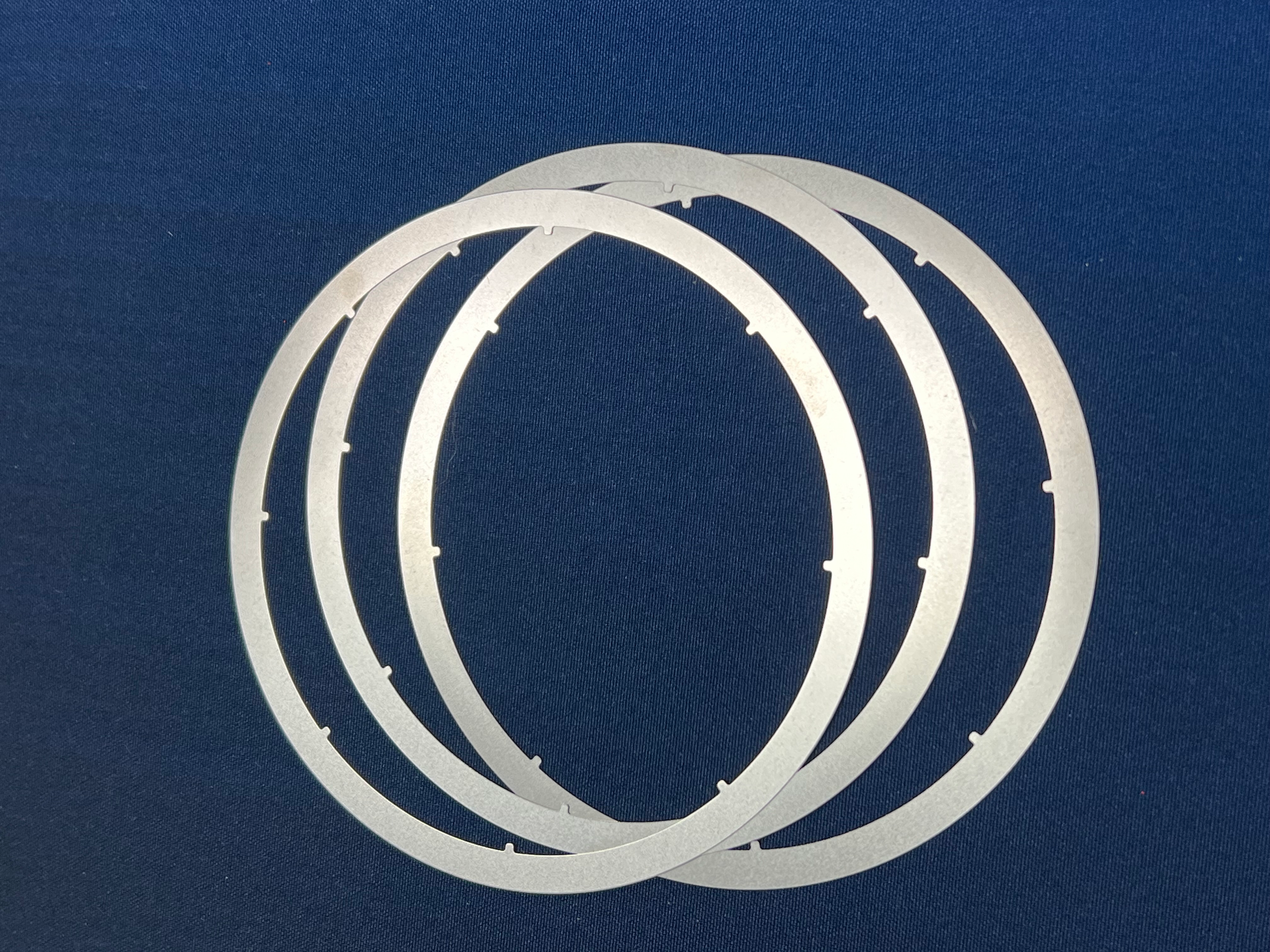

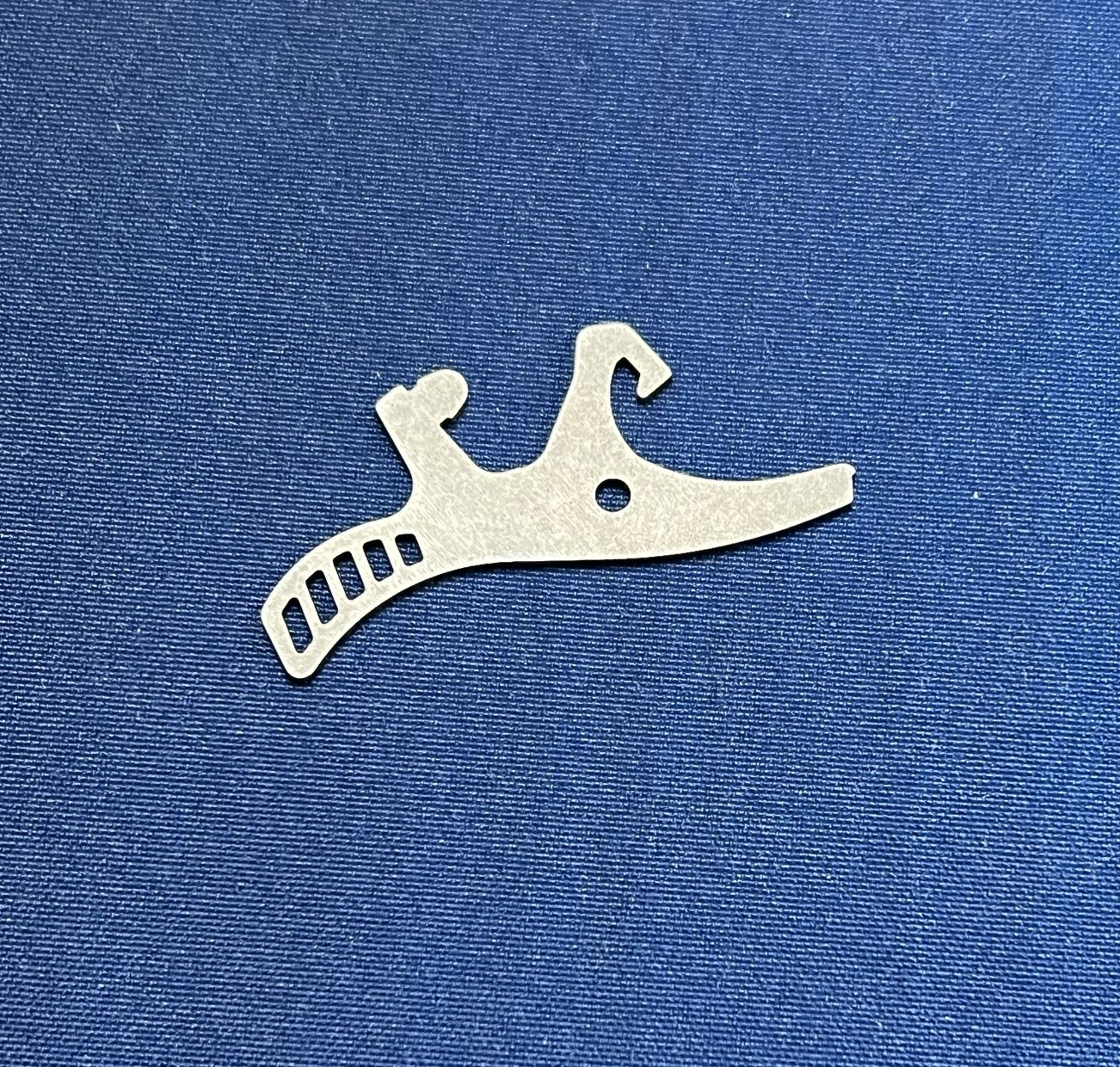

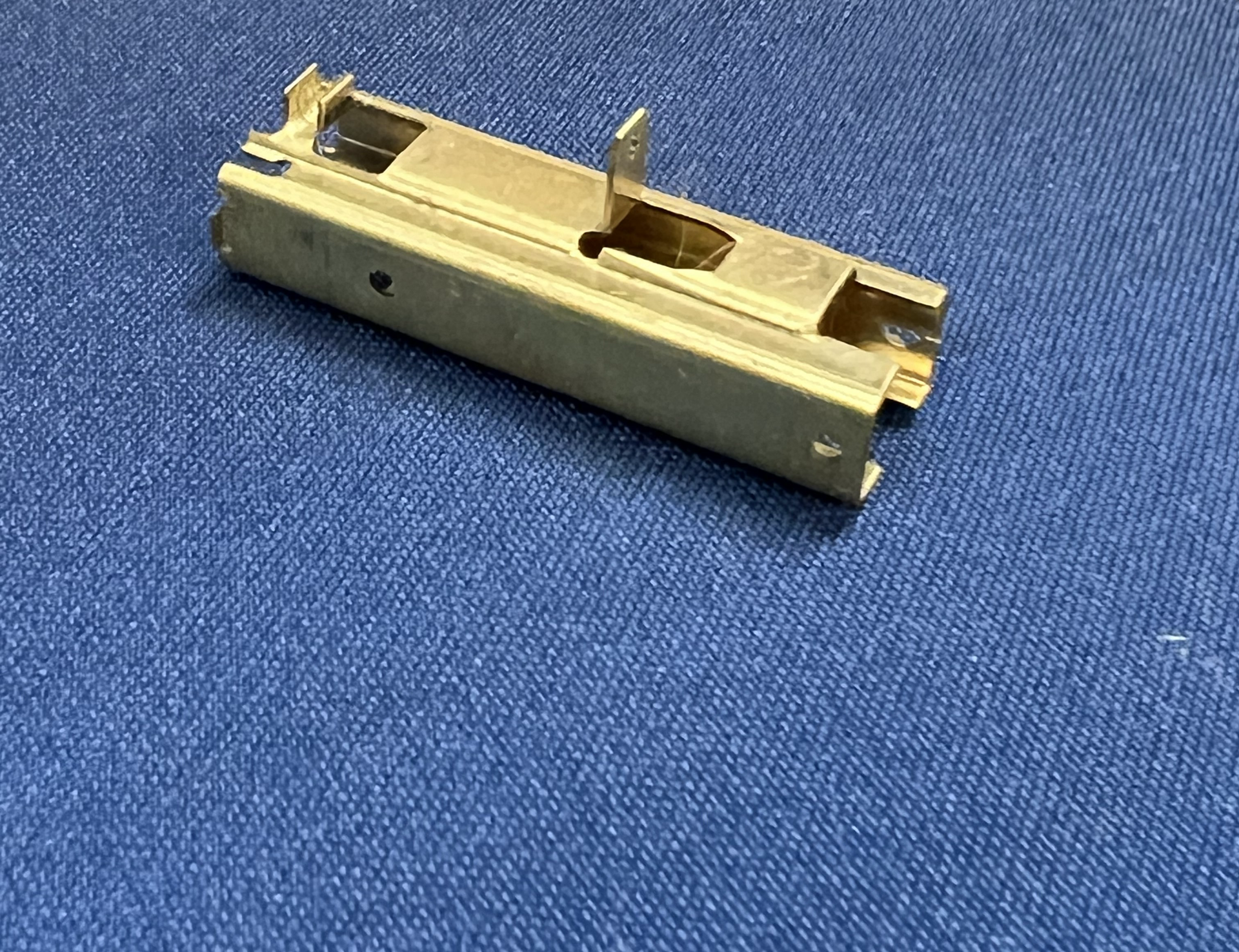

Showcase of Our Manufactured Parts

We manufacture rapid prototypes and low-volume production orders for customers in multiple industries: aerospace, automotive, defense, electronics, hardware startups, industrial automation, machinery, manufacturing, medical devices, oil & gas and robotics.

MARION MANUFACTURING'S FACTORY TOUR

Step Inside and Tour Our Factory

Marion Manufacturing takes pride in operating one of the most advanced factories in the metal stamping and precision components industry. We invite you to watch our factory tour video to glimpse into our advanced capabilities and processes, reflecting our 75-year commitment to excellence in American manufacturing.