Precision Manufacturing With Unmatched Service

Long-standing Expertise and Commitment to Quality Manufacturing Since 1934

ABOUT MARION MANUFACTURING

Creating Solutions For Over 75 Years

Since 1946, Marion Manufacturing has been a leader in progressive metal stamping and precision metal components. With over 75 years in the industry, our mission remains to deliver high-quality American-made products. Watch our video to learn more about our story and the long history of pride we have in our industry.

Our Manufacturing Capabilities Customized For You

At Marion Manufacturing, our agility is a distinct advantage in our services, appreciated for the short lead times and high efficiency we offer. We create tailored solutions that effectively tackle significant challenges, consistently exceeding customer expectations.

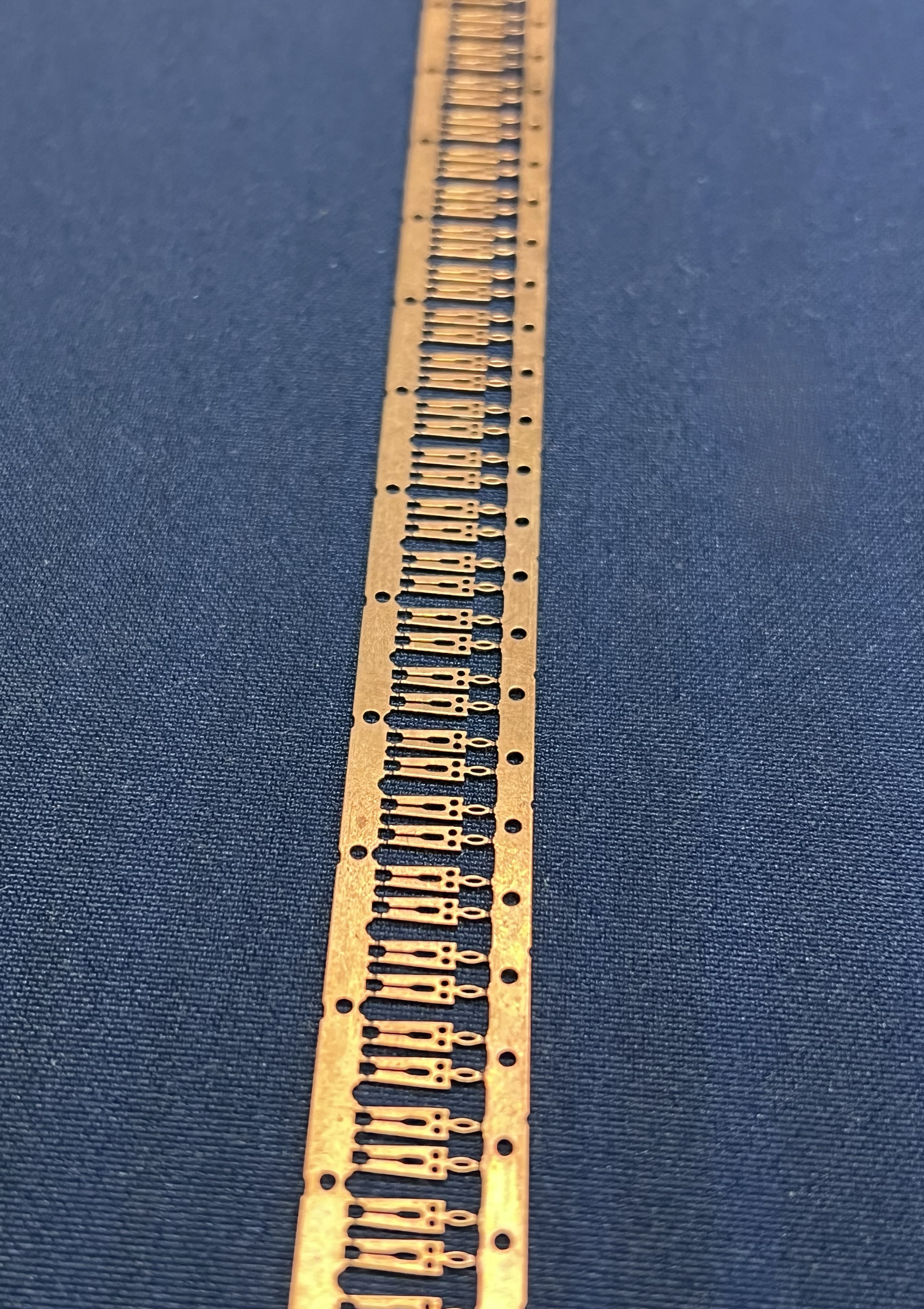

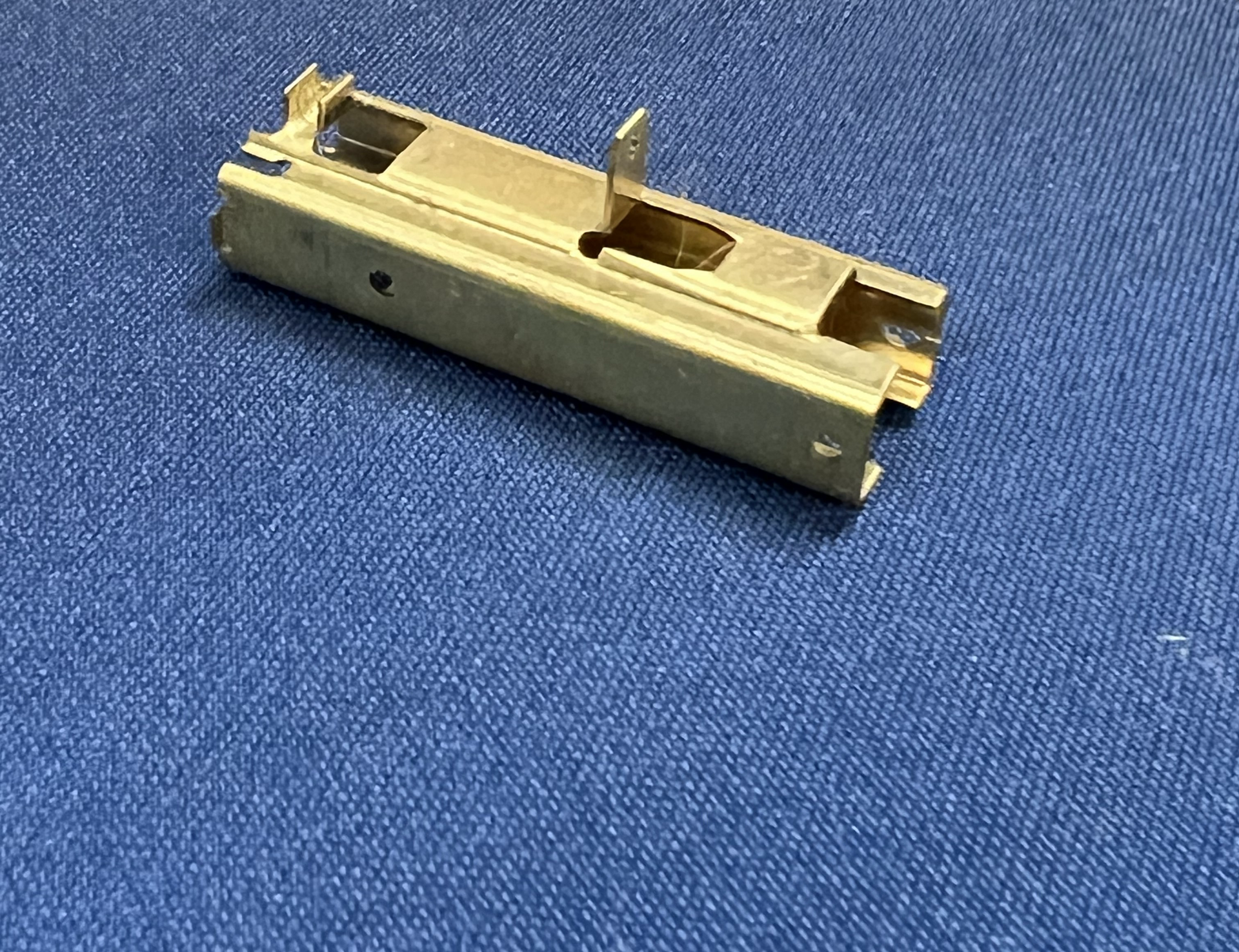

Metal Stamping

Stamping, forming, cutting

Experience precision and efficiency with our high-speed progressive metal stamping at Marion Manufacturing. Leveraging advanced technology and decades of expertise, we specialize in manufacturing complex components with exceptional accuracy.

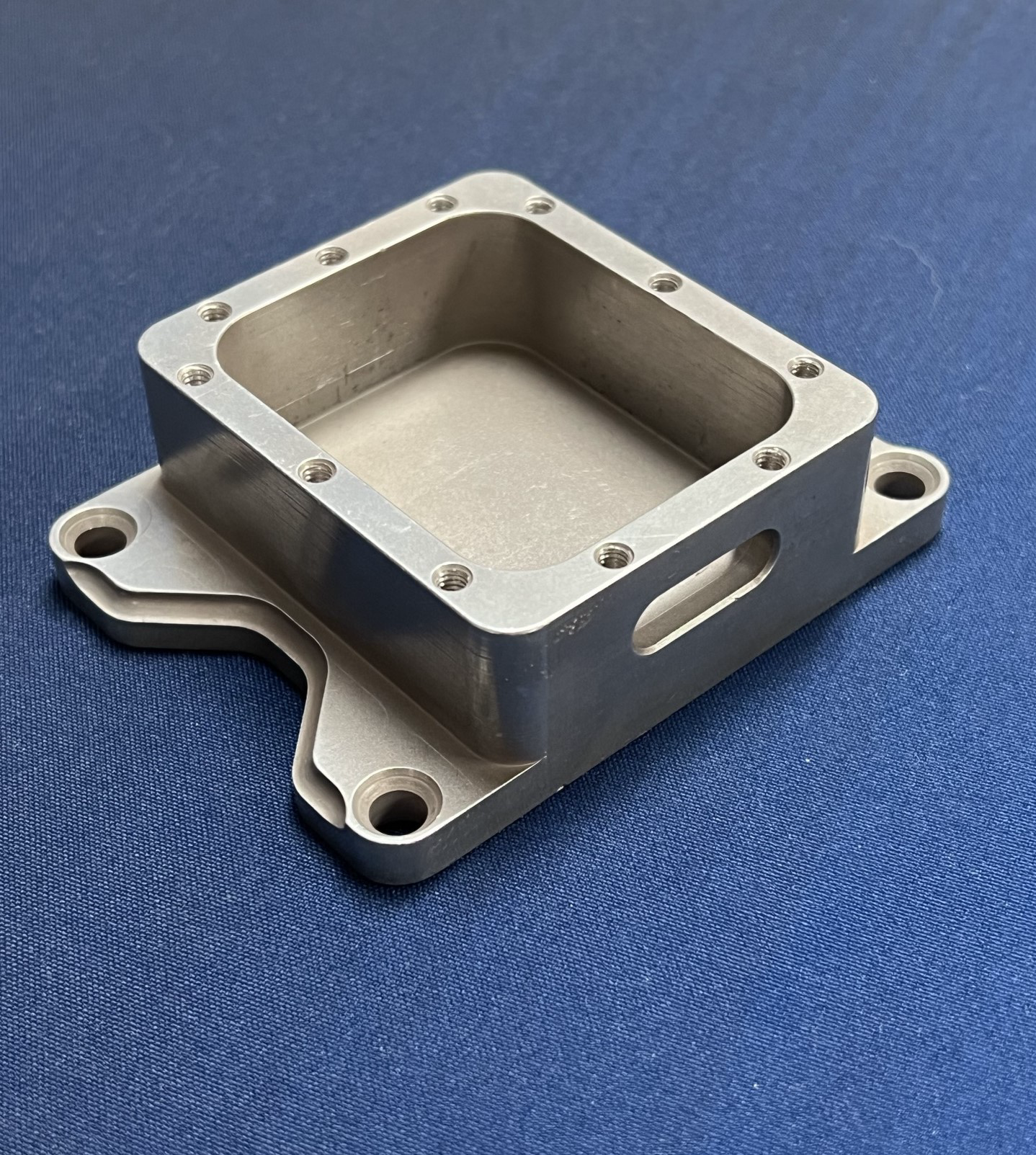

CNC Machining

Milling, drilling, finishing

Marion Manufacturing pushes the boundaries of precision and sets the standard in CNC machining. Combining cutting-edge technology with deep expertise, we excel in producing intricate and highly reliable components across a variety of materials.

Laser Cutting

Cutting, shaping, finishing

Redefining precision and flexibility, our laser cutting services at Marion Manufacturing harness advanced laser technology to precisely cut neoprene, metals, and plastics. We ensure rapid turnaround times while adhering to the highest quality standards.

Our Top Markets for On-Demand Manufacturing

We excel in delivering high-quality, American-made products tailored to meet the demands of our diverse markets. View our full range of industries we serve below.

The Marion Manufacturing Standard

Marion Manufacturing applies a meticulous set of standards to every custom part, ensuring quality and consistency for all components.

Quality Assurance

We ensure each product surpasses industry standards, embodying our commitment to reliability and quality excellence.

Production Efficiency

Our team upholds high production efficiency and precision, significantly cutting lead times while enhancing product quality.

Prompt Delivery

We prioritize ensuring on-time delivery, optimizing our workflows to reliably meet even the most stringent timelines.

Our Customer Order Success Process

Our streamlined process ensures each project is executed with precision, from blueprint to final production.

Contact Our Team

Reach out to our Sales team to get started with your NDA, blueprint review, EAU review, and manufacturing feasibility.

Submit Specs & Files

Securely upload your CAD files and confirm pertinent quality specifications of your part design directly with our team.

Receive Your Quote

Receive a detailed quote that includes lead times and pricing. Approve the quote to move forward with the tool build, first article, and production.

Delivery Right To You

Every order benefits from prompt delivery, ensuring it arrives on schedule to meet customer satisfaction.

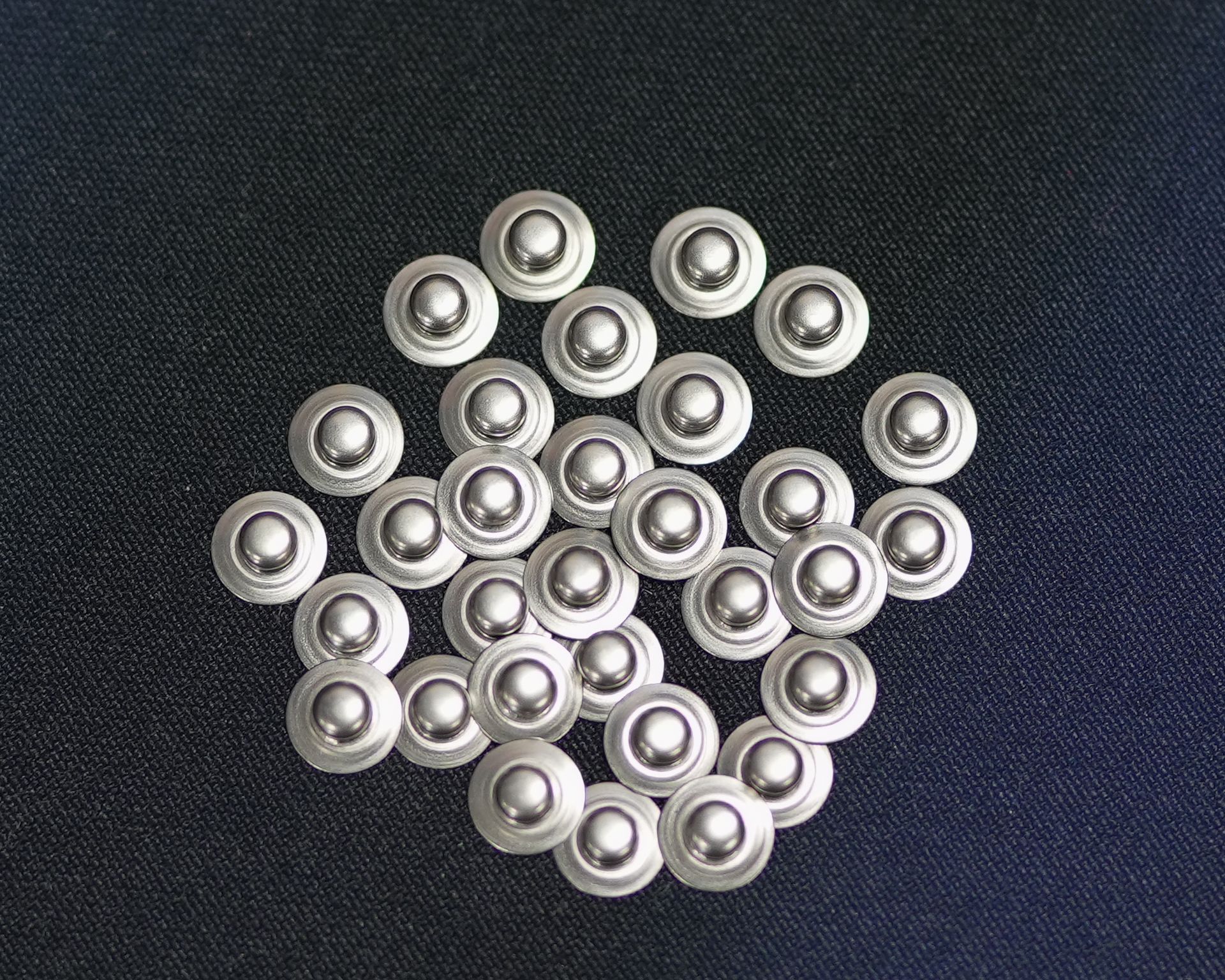

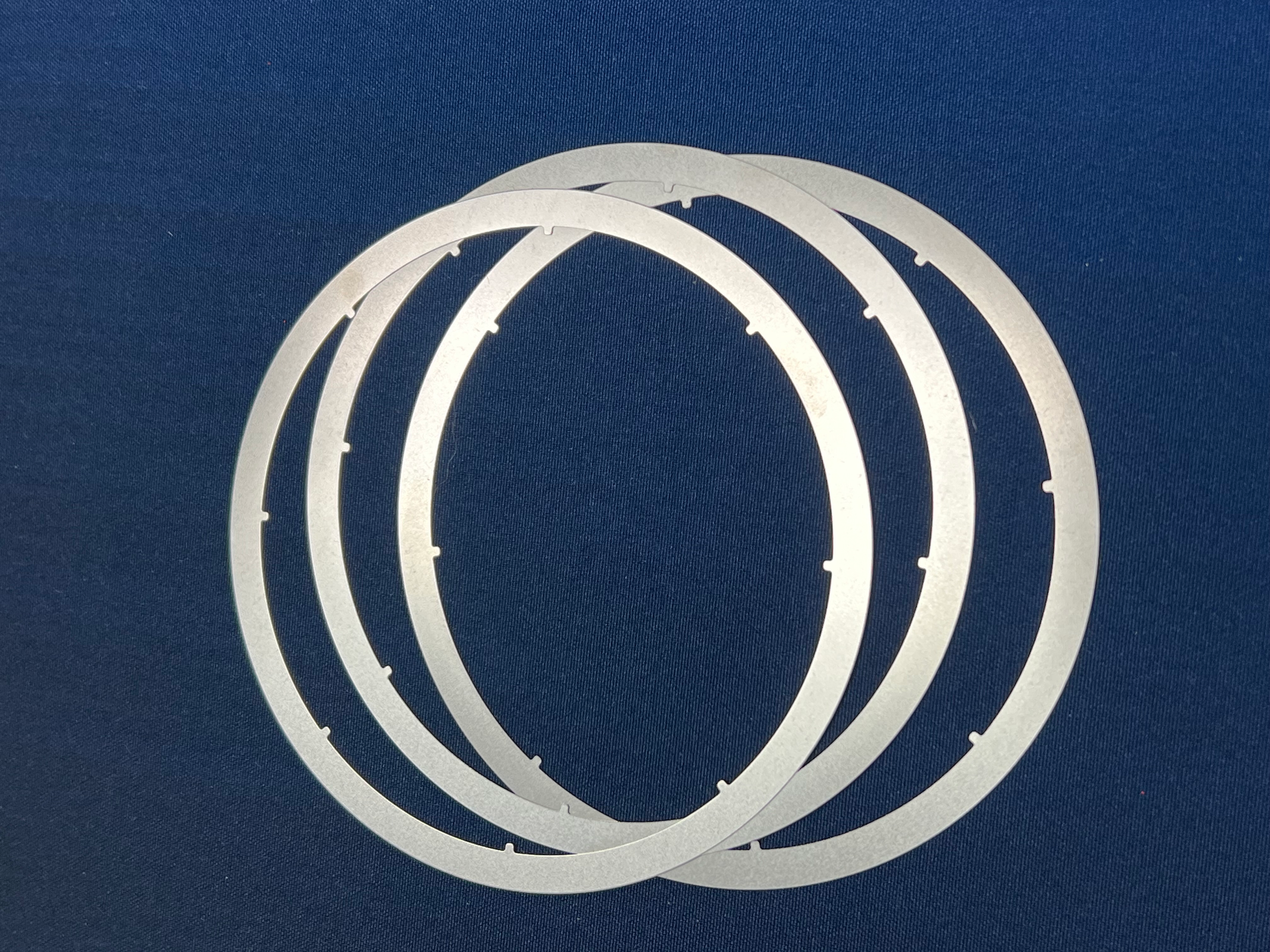

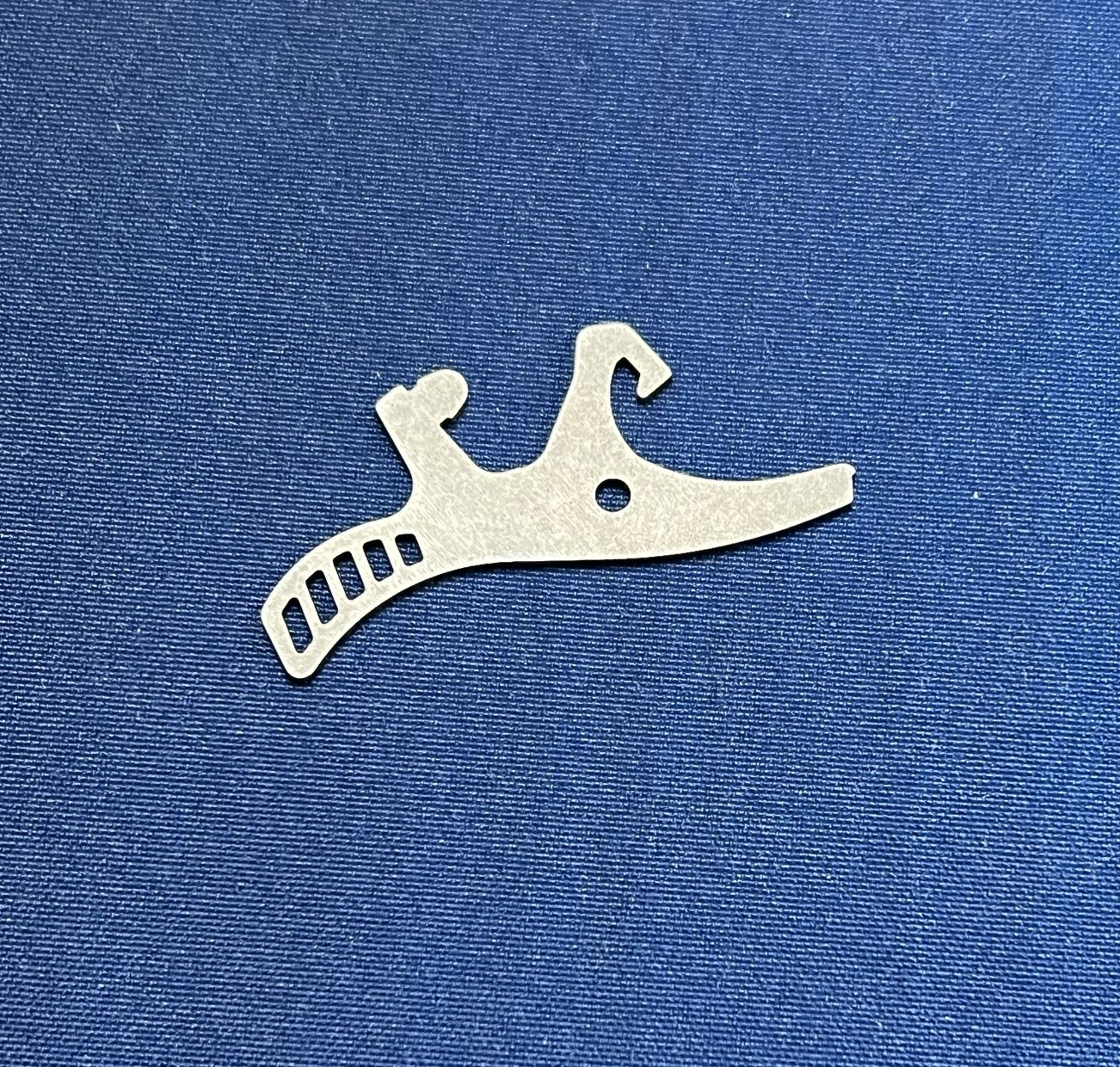

Showcase of Our Manufactured Parts

We manufacture low-high volume production orders for customers in multiple industries: aerospace, automotive, defense, electronics, hardware, startups, industrial automation, machinery, manufacturing, medical devices, oil & gas and robotics.

MARION MANUFACTURING'S FACTORY TOUR

Step Inside and Tour Our Factory

Marion Manufacturing takes pride in operating one of the most advanced factories in the metal stamping and precision components industry. We invite you to watch our factory tour video to glimpse into our advanced capabilities and processes, reflecting our 75- year commitment to excellence in American manufacturing.

Request A Quote

Ready to start your next project? Begin your quote today with Marion Manufacturing by calling us at (203) 272-5376 or completing the form. Below are the next steps in our process that you can expect.

A team member will contact you within one business day.

We will schedule a time to discuss your requirements.

Get a detailed quote with lead times and pricing for your project.

Business Hours

- Mon - Fri

- -

- Sat - Sun

- Closed